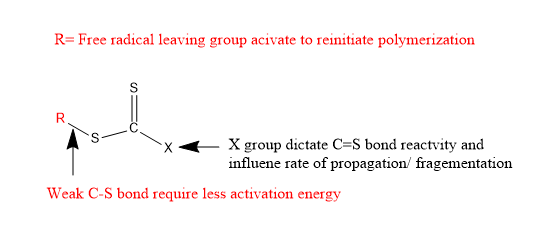

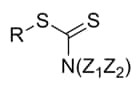

About 15 years ago members of an Australian Commonwealth Scientific and Research Organization (CSIRO) team discovered the RAFT polymerization method published in Macromolecules. 31(16):5559-5562. The elegant process follows radical-initiated growing polymer chains to degenerative transfer reactivity from one to another through the use of functional groups (based Di thioesters, Tri thiocarbonates, Xanthates and Dithiocarbonates).

RAFT agents assist to minimize out-of-control growth of propagation and prevent unwanted chain transfer termination events from occurring, effectively controlling polymer architecture and properties like molecular weight and polydispersity of end products. The control of microstructure of polymer such as tacticity by this process can not be tailored to the best of our literature survey. These RAFT reagents are most of them are commercially available and viability for its commercially available increase day by day. One of the important feature of this process of polymerization is absence of any cytotoxic heavy metal components (unlike ATRP process).

Uniqueness of RAFT

RAFT molecule is compatible with most functional groups and solvents, monomers, including water or no solvent. RAFT polymerizations do not require rigorous purification of solvents or monomers (around 97-98% acceptable). especially when compared to living anionic or cationic polymerizations. RAFT moiety can be tailored to bear un touch functional group that generate the possibility to produce polymers with monochelic or telechelic quantitative functionality, for further processing of polymers, furthermore the RAFT technique requires no special equipment or vacuum glassware and some time can be carried out in a simple round bottom flask at 40 oC to 90 oC with the use of properly selected free radical initiator such as V70 and AIBN.

The draw back of the process are;

- Strong smell of RAFT ( presence of thiol) while using

- Some time formation of side product difficult to remove on ppb scale as required by electronic industries and pharma industries

Classification of RAFT in General.

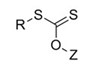

- RAFT Xanthates Group: Where Z is typically an alkyl (ethyl) moiety

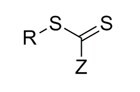

- RAFT Dithioesters Group: Where Z is typically a phenyl moiety.

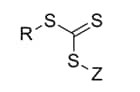

- RAFT Trithiocarbonates Group : Where Z is typically an alkyl long carbon group (C12H25, etc.)

- RAFT Dithiocarbamates GROUP Z1 is typically -Methyl and Z2 or other alkyl moiety

RAFT EFFICACY